Successful participation of elmor Ltd. at the Cannabis Business Expo and conference in Zurich, September 11th-12th, 2021

The CB Expo – Cannabis Business Expo brought together leading companies from Switzerland, Europe and overseas with products related to CBD, medical cannabis, cultivation, paraphernalia and services, supplemented by lectures by top-class experts from research,...

Customized automation, thanks to elmor counting and filling devices

Seed dealers and rhinestone dealers have a lot in common. Their products are often sold piece by piece and need to be counted. The dosage based on weight is usually too imprecise. Small companies do this job manually. But as the business develops, the question soon...

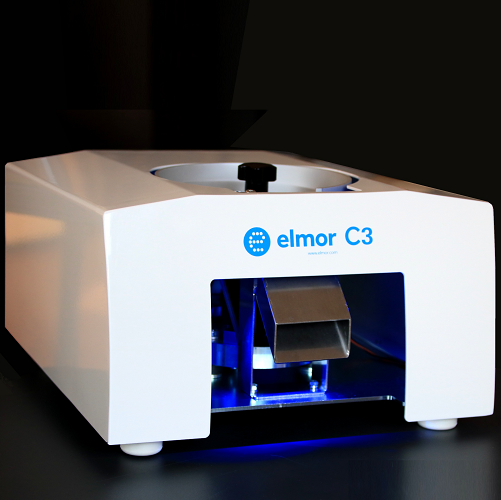

Determine the Thousand Grain Weight precisely with the elmor C3 seed counter

The thousand grain weight TGW (also called 1000 grain mass) is an important quality criterion in seed tests, which must be determined with great accuracy. The TGW or the derived value “number of parts per gram” are also an important parameters in the...

Extended range of feeder bunkers

Feeder bunkers are used to refill the elmor C1, C3 or CX counting machines continuously and unattended. These devices are available with a storage volume of 2.5 liters to more than 30 liters. For light parts such as seeds, a linear vibratory feeder is the best choice....