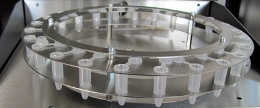

Carousel filler for bags and vials elmor 780

The elmor 780 carousel filler can be combined with our seed counters elmor C1 and elmor C3.

The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine, PE or composite material.

The carousel tray can easily be removed and reinserted and the control circuitry of the equipment recognizes automatically if a tray has empty positions; these positions are skipped so that no seeds get lost.

The carousel filling devices are individually designed depending upon the requirements of the customers. The type and size of the containers as well as the number of positions per tray can be selected within wide range.

Examples

Top: C1 seed counter with a carousel filler built for 12 glassine bags.

Middle: C1 seed counter with a carousel filler built for 16 glass dishes used for sample preparation in a seed quality test lab.

Bottom: Carousel insert for 25 Eppendorf tubes (trademark of Eppendorf)

Technical description

The Carousel filling device consists of a base unit with control and drive and the removable carousel insert made of stainless steel. The containers are loaded or unloaded using the taken-out carousel. With two or more carousel inserts, a high filling throughput can be achieved.

The number of positions depends upon the width of the bags, respectively, the diameter of the containers. The maximum number of filling positions amounts to 15 bags or 25 containers.

A special version of the basic device also allows the processing of two different position numbers in the ratio 2:1, for example, 24 tubes or 12 bags.

In the base unit a maintenance-free drive is installed which needs no adjustments. This results in a long service life even in rough and dusty environments.

The carousel can be equipped with any type of containers. Examples are: Glassine bags, envelopes, vials, small containers or tubes with only a few mm in diameter.

Before each filling operation, it is checked whether a container is present or not at the current position. Empy positions are skipped to avoid a loss of parts to be filled.

Modes of operation

Automatic: All occupied positions of the carousel are filled, then the device stops and waits for the restart.

Permanent: The available positions are constantly being filled. The filled containers can be replaced manually on the front.

Dimensions: 360 x 600 mm, the height depends of the container height. Weight about 20kg

elmor Green Design

Our label for:

- high energy efficiency

- longevity

- no standby power loss

- most components may be recycled

- production without solvents, ROHS conformity